Water is essential for human survival on Earth and in space. A typical person requires between 3.5 to 15 liters per day. Yet launching large quantities of water up to the International Space Station (ISS) is terribly expensive, and would be a major impediment to future space settlement. So NASA has made water recycling a vital part of closing the life support “loop”. Meanwhile, water is often in short supply even on the Earth, especially in a clean, drinkable form.

First Steps

Russia’s space station Mir recycled cosmonaut sweat. An earlier NASA method of water re-use involved separating waste water into hydrogen and oxygen. The oxygen could be used for breathing and thus reduce the amount of oxygen that needed to be transported to ISS (NASA 2008).

NASA’s Current System on the ISS

NASA’s current water recycling system on ISS is the Water Recovery System (WRS), part of the Environmental Control and Life Support System (ECLSS). WRS water purification machines on the ISS cleanse wastewater in a three-step process. WRS first filters out particles and debris. Then, urine is processed though vapour compression distillation (VCD), while humidity condensate passes through multi-filtration beds to remove organic and inorganic impurities.

Products of the vapour and multi-filtration are mixed together and passed to a catalytic oxidation reactor that removes volatile organic compounds (VOC) and kills bacteria and viruses” (Carter at al. 2008). This system is designed to recycle about 90% of ISS waste water. ISS occupants are supplied with hydrated food that makes up the remaining 10%.

Similar technology is also being used in the field. Waterlife International produces a unit for local use. They have engaged in projects in Kenya, Rwanda, South Sudan and Cambodia. They are in talks to supply a provincial government in South Africa. Also see the Water Security Corporation.

Next Generation System

To do even better, the Alternative Water Processor (AWP) is currently being developed by NASA’s Next Generation Life Support Project, under the Game Changing Development Program. It will support a crew of four each with 11 liters of water per day on a long-duration space flight mission. On such missions, food will likely be freeze-dried rather than hydrated, so it will not be available as a source of water. Hence, the newer AWP must have an even higher recovery rate than the older WRS.

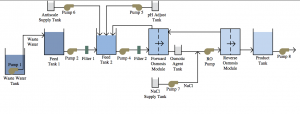

AWP has a membrane-aerated bioreactor to destroy organic contaminate and a forward osmosis secondary treatment (FOST) system to remove dissolved solids. FOST uses saltwater as the drawing solution, then reverse osmosis is used to remove the salt, according to Michael Flynn, a research engineer at the NASA Ames Research Center. (Also see NASA 2013)

Construction of the first generation FOST was recently completed at the NASA Ames Research Center. The system recently shipped to the NASA’s Johnson Space Center. FOST will undergo integrated testing with the membrane-aerated bioreactor, designed by Texas Tech University and constructed by NASA Johnson Space Center. (NASA 2013)

“Inside the water recovery system is an evolving set of technologies with great promise,” said Flynn. “Ultimately, these systems will continue to evolve and become increasingly more complex, integrated and smaller.” (NASA 2013) The new system has two major advantages. First, it allows for 95% recycling of waste water. Part of this improvement is due to the use of bioreactor to treat urine, which will avoid the need for highly toxic chromic acid. Second, the new system also processes a higher volume of waste water, so that crew will be able to engage in a greater range of water usage, such as hand-washing and laundry. Also, this new system is lighter, takes up less space and requires less energy per gallon processed, so it is better-suited for long-duration missions.

Bringing It Back to Earth

NASA’s FOST system is already finding use on Earth. NASA researchers installed a larger version of FOST in its Sustainability Base, which in combination with other water-saving technologies integrated into the building, is expected to reduce greywater consumption by more than 90 percent. (Total tap water usage is reduced by 40%.) Flynn points out that additional capabilities of FOST in the Sustainability Base include the ability to do long duration testing and failure prediction. It is certainly safer to do this on Earth than in space.

The Future

NASA’s next step may take inspiration from living systems, according to Flynn. Biomimicry is a form of engineering that imitates living systems. For example, in the human body, the small intestine is a highly efficient water absorption and filtering system that works reliably for many decades. It is also self-repairing. NASA is looking towards designing a system that emulates the positive qualities of the small intestine.

A Brief Lesson in Water Filtering

Knowing a few terms can help understand NASA’s technology. Water is typically recycled from several sources. Greywater is waste water from showers and sinks, and can include water from humidity. Blackwater contains fecal matter and urine, such as from toilets. Reverse osmosis (RO) uses physical pressure to push water through a filter. In contrast, forward osmosis (FO) draws water through a filter using an ionic medium such as sugar or salt water, and has several advantages, such as reduced pore clogging.

Pingback: Will Finding Water On The Moon Be the New “Striking Oil”? | SustainSpace